LOW PRESSURE VOLUMETRIC/METERING DOSERS WITH DIVORCED TECHNOLOGY

Pneumatic volumetric dosers for precision impulsive doses.

Suitable to dose greases, oils, pastes and silicone-based fluids low-to-high viscosities.

Dosing range from 0,003 to 0,75cc according to selected model.

Dose manually adjustable through graduated knob.

Materials : aluminum, brass.

Divorced technology for longer durability in presence of heavy duty applications, extremely high viscosities or aggressive/abrasive fluids.

LOW PRESSURE VOLUMETRIC/METERING DOSERS

Pneumatic volumetric dosers for precision impulsive doses.

Suitable to dose greases, oils, pastes and silicone-based fluids low-to-high viscosities.

Dosing range from 0,003 to 0,75cc according to selected model.

Dose manually adjustable through graduated knob.

Materials: aluminum, brass.

Inlet fluid pressure max 15bar.

TABLE-TOP DOSING SYSTEMS

Table-top dosing systems and equipments for fluid application, manually activated or semi-automatic.

Suitable for grease, oil, paste, silicone or resin applications, they can be equipped with a variety of dosing elements according to fluid or process.

Integrated systems, complete with custom tailored fixtures and supplied with full functional tests at TM, where customers can see and learn how to operate their equipment.

HAND-HELD DOSING SYSTEMS

Hand-held dosing systems and equipments for fluid application, manually activated.

Suitable for grease, oil, paste, silicone or resin applications, they can be equipped with a variety of dosing elements according to fluid or process.

Integrated systems, complete with custom tailored elements and supplied with full functional tests at TM, where customers can see and learn how to operate their equipment.

TWIN COLUMN ELEVATOR EXTRUSION PUMPS FROM 1 TO 200 LT

Extrusion pumps featuring

twin-column pneumatic elevator.

Suitable to feed dosing systems with greases, pastes, medium-to-high viscosity silicones and resins.

Dashboard includes full frontal controls and indicators.

Size fit for 1-3 liter canisters, 5 to 50 liter pails and 200 liter drums/barrels.

Custom made extrusion disc/plate sized upon packaging.

Optional: minimum level pump stopping device.

2-hand safety controls.

VOLUMETRIC/METERING LINEAR DOSERS

Electric volumetric linear dosers for high precision dosing applications.

Suitable for lubricants, pastes, silicones, one- or two- component resins, gap fillers, thermal greases and fluids from low to high viscosity, also with aggressive chemical or physical properties.

Volumetric dispensing of microdoses, continuous strings or precision filling.

Brushless or stepper motor integrated.

Requires dedicated TM electronic drive and/or control unit/panel.

Possibility of custom-made projects for size, capacity and dosed fluids.

PROCESS CONTROL UNITS

Dosing process control systems.

Devices and accessories which can be integrated or added on TM

impulse or continuous dosing systems/elements.

Suitable for lubricants, resins, silicones, pastes, glues and adhesives.

Technologies of flow detection, dispensing detection and volume detection/control for dose and process validation, against possible air bubbles, dosing/feeding/flow anomalies or nozzle clogging.

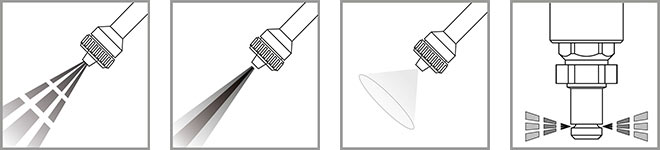

SPRAY GUNS

Pneumatic air spray guns, non volumetric, for continuous or impulsive/spot spray applications.

Suitable for low to medium-high viscosity fluids such as oils, glues, silicones, emulsions, water, paints, inks, solvents, greases, pastes, resins, etc. Anti-leak needle closure on the tip and various spray nozzles available.

Flow adjustable mechanically with finely milled ticking knob.

Materials: aluminum and stainless steel. Suitable for straight feeding from pressure tank or paired with volumetric/metering impulsive or continuous dosers for precision spraying and microspraying applications.

VACUUM-BASED DOSING MACHINES

Custom machines and technologies for precision filling or encapsulating processes under vacuum conditions, for electronics, cinematics or hydraulics like shock absorbers, hinges or dampers.

The Vacuum Filling family uses TM's patented degassing processes and vacuum injection techniques which are developed custom for each project and component, so the customer is followed personally at every step and the best results are guaranteed.

Possibility to develop standalone units or automated units to be inserted within automated assembly lines.